Here you'll find dehumidifiers for household use and for professional water damage drying. Dehumidifiers for keeping damp basements or apartments dry, as well as for drying laundry.

Dehumidifiers

TROTEC Trotec TTK570ECO Dehumidifier

A very powerful construction dehumidifier with brutal dehumidification strength. Perfect for drying large construction sites and for the effective drying of water damage. This dehumidifier has consistently omitted everything that is unnecessary for continuous operation. It has neither a display nor a hygrostat (a plug-in hygrostat can be optionally ordered if needed). This makes it very easy to operate, safe from tampering, and exceptionally affordable in price for this performance class. On the other hand, it has everything needed for quick drying: strong dehumidification performance, hot gas defrosting, hour counter, as well as large wheels and a handle for easy mobility on construction and damage sites. Easy handling "The commissioning is child’s play. Set up - connect the hose - plug in - flip the main switch - done!" The operation continues until the dryer is reinstalled. As long as the device is connected to the power grid, it runs reliably and there are no settings that can be accidentally changed or manipulated. This also applies in the event of a power outage: when the power returns, the dehumidifier resumes its task with unchanged settings. Thanks to the professional hot gas automatic control, operation in cooler environments is also possible without any issues, although the dehumidifying power, as with all condensation dryers, decreases at low temperatures. The installed finned evaporator (cooling element) has an exceptionally high efficiency in temperate environments and can dry the air to just below 40% relative humidity. Furthermore, the dryer is equipped with a rolling piston compressor. This means that it can be transported and stored in any position. Optional Hygrostat "Should a hygrometer for regulating the target humidity be required at any point, the dryer is prepared so that the Trotec Hygrostat HG110 can be connected directly via a jack plug. Please note the accessories." Direct hose connection With dryers of this strength, collecting water in an integrated bucket makes little sense, as it would constantly fill up. The water extracted from the air is therefore drained through a directly connected hose. The hose must be laid with a downward slope, as there is no pump integrated into the dryer. Freestanding condensate pumps are optionally available if the water needs to be transported upwards or over a distance. Suitable for unattended continuous operation This "TTK" is suitable for longer, unattended drying operations. The exact operating time can be precisely determined with the standard integrated hour meter. This is particularly useful for commercial applications. Thanks to the meter, it can also be tracked whether the device was always in operation or if it was accidentally or intentionally turned off. Hydrofluorolefin (R-454C) as an environmentally friendly refrigerant in dehumidifiers "Every year, several million tons of environmentally harmful CO2 emissions (greenhouse gases) are released into the air due to synthetic refrigerants. Therefore, the use of alternative refrigerants is one of our most important goals. By using hydrofluoroolefin (R-454C) as a refrigerant, this dehumidifier makes a valuable contribution to climate protection." The natural refrigerant hydrofluoroolefin (R-454C) is an organic compound and belongs to the hydrocarbons. Unlike synthetic refrigerants, the environmentally friendly hydrofluoroolefin (R-454C) has neither ozone depletion potential (ODP=0) nor a significant greenhouse effect (GWP=146). Supplement plus for the environment: Due to its excellent thermodynamic properties, hydrofluoroolefin (R-454C) is a particularly energy-efficient refrigerant, thereby additionally reducing your energy costs. Advantages at a Glance • Affordable price with strong performance in the commercial sector• Thanks to hot gas defrosting, it can also be used in cooler environments.• Robust steel construction with large wheels and guiding handle• Suitable for continuous operation• Thanks to the roll piston compressor, it is transportable and storable in any position.• External hygrometer connection Technical data dehumidification performance at 30 °C / 80 % r.H. 100 liters / day air volume 1000 m³/ h Maximum room size 250 m² (750 m³) Minimum room size 8 m² (30 m³) temperature range 5 - 32°C Moisture range technical Moisture Range Practice 30 - 90 % r.F. 40 - 90 % r.H. (lamella evaporator) Voltage 220 - 240 V/50 Hz rated current consumption max. 8.1 A Power consumption max. 1920W Recommended Coverage 16 A Cable length approx. 2 m Plug EU plug with Swiss adapter refrigerant R454C (1000g) GWP146 water bucket no bucket operating noise 67 dB(A) at 1 m distance 64 dB(A) at a distance of 2.5 m Dimensions L x W x H 538 x 698 x 1006 mm incl. guide rail and rollers Weight 64 kg defrosting automatic Heissgas dehumidification automation Continuous operation, an insertable mechanical hygrometer is optionally available. Ventilator radial, single-stage blower prefilter and operating hour meter and Continuous operation possible and Display no memory function yes (automatically saves set values) hose connection yes, not included in the delivery (suitable inner diameter: 12mm) guarantee 2 years

Fr. 1'490.00 Fr. 1'043.00

TROTEC Trotec TTK125S Dehumidifier

Professional construction dehumidifier with large bucket A high-quality dehumidifier for commercial use and water damage drying, manufactured in Europe. Its impressive exterior appearance is matched by its internal values: all electrical components are specially encapsulated, protecting the electronics from harmful deposits that could impair their function and longevity. Therefore, this dryer is also ideally suited for use under demanding conditions. Thanks to its maintenance-friendly design, it is easy to care for. "Compared to more affordable piston compressors, the high-quality 0.58 kW rotary compressor installed here offers the advantage of higher performance with comparatively lower power consumption – and additionally provides reserves for high dehumidification performance even in unheated rooms."In addition, the high-quality hot gas defrosting automatic system ensures a much more efficient dehumidification performance compared to other defrosting devices, without time interval-related defrosting pauses during which no dehumidification takes place. Propane (R290) as an environmentally friendly refrigerant in dehumidifiers Annually, several million tons of environmentally harmful CO2 emissions (greenhouse gases) are released into the air due to synthetic refrigerants. Therefore, the use of alternative refrigerants is one of our most important goals. By using propane (R290) as a refrigerant, this air dehumidifier makes a valuable contribution to climate protection. The natural refrigerant propane (R290) is an organic compound and belongs to the hydrocarbons. Unlike synthetic refrigerants, environmentally friendly propane (R290) has neither ozone depletion potential (ODP=0) nor a significant greenhouse effect (GWP=3). Supplement plus for the environment: Due to its excellent thermodynamic properties, propane (R290) is a particularly energy-efficient refrigerant, thereby additionally reducing your energy costs. User-friendly Thanks to its durable housing, ergonomic grip recesses with an internal grip clip, and four sturdy wheels with a roll stop, the device is ideally suited for use on construction sites and for drying water damage. However, these advantages are also appreciated in commercial spaces or in private basement environments. The storage is also well thought out: two practical stacking grooves on the top of the device allow for a stable and space-saving stacking during transport and in storage. An integrated operating hour meter reliably documents the exact duration of use even during longer drying operations. Integrated compressor thermal protection with automatic shut-off In drying operations with extremely high humidity and simultaneously high temperatures – for example, during water damage restoration – refrigerant dryers quickly enter their red performance zone. Here, the catchy "35 rule" applies: water damage above 35 degrees reduces the dryer’s lifespan to below 35%. However, this is not a question of component quality, but pure physics, which applies independently of the manufacturer to all refrigerant dryers on the market. While most professional condensate dryers can still operate without issues at moderate humidity around 70% r.F. up to 35 °C, very high humidity combined with high room temperature results in significantly more energy being supplied to the humid air, which must be additionally "processed" through the refrigerant. Consequently, the pressure of the refrigerant in the system increases immensely, leading to a destructive load on the compressor. Although the dehumidifiers will initially continue to operate, they will do so well beyond their limit "deep in the dark red zone," resulting in an extremely shortened remaining lifespan. "Therefore, the commercial dehumidifiers of the TTK-S series are equipped with an integrated compressor thermal protection for the active preservation of your devices:"Sensors continuously monitor the thermal load of the compressor. If the temperature is within the defined operating range, the integrated heat protection indicator pulses in a long sequence, indicating optimal operation of the dehumidifier. As soon as the temperature exceeds the critical threshold of 35 °C, the automatic system switches off the compressor to protect it, while the fan continues to operate, and automatically reactivates the compressor as soon as the 35° threshold is fallen below again. This protection not only significantly extends the lifespan of the dehumidifiers, but also prevents thermal damage to materials in the room and the building structure during their use. Options • Dual meter available for additional recording of electricity consumption.• high-performance condensate pump for permanent drying with a pumping capacity of up to 50 m distance and a maximum delivery height of 4 m Advantages at a Glance • High dehumidification performance even at low temperatures • Maximum dust and moisture protection for all electrical components• Extremely maintenance-friendly design • Optimal handling characteristics • Thanks to the roll piston compressor, it is transportable and storable in any position. • Practical stacking groove for stable, space-saving storage and transport • Multistage capability with identical models• Practice-oriented industrial design• Made in Europe Technical data dehumidification performance at 30 °C / 80 % r.H. 28 liters / day air volume 250 m³/ h Maximum room size 70 m² (175 m³) Minimum room size 8 m² (30 m³) temperature range 5 - 32°C moisture range 35 - 90 % r.F. Voltage 220 - 240 V/50 Hz rated current consumption max. 2.3 A Power consumption max. 500W Recommended Coverage 10 A Cable length approx. 3 m Plug EU plug with Swiss adapter refrigerant R290 (150g) GWP3 water bucket 6 Liter operating noise 52 dB(A) at 1 m distance 49 dB(A) at a distance of 2.5 m Dimensions L x W x H 375 x 345 x 603 mm Weight 26 kg defrosting automatic Heissgas dehumidification automation Hygrostatgesteuert Ventilator axial, single-stage blower automatic shut-off when bucket is full and prefilter and Timer no Continuous operation possible and memory function yes (mechanically stores set values) hose connection yes, short hose piece included in the delivery guarantee 2 years

Fr. 1'090.00

Master Master DH752 Dehumidifier

The combination of compact dimensions and high dehumidification performance makes this model ideal for construction drying and drying after water damage. In addition, the dehumidifier is excellent for keeping commercial properties, archives, and production areas dry. Thanks to its two large wheels and practical handle, it can be easily moved across various objects. Operation 'Through the digital control panel at the front, the desired target humidity can be selected in 1% increments between 40-80%. Continuous operation is also possible. The set values can be saved at the push of a button. This way, in the event of a power interruption, operation will automatically continue with unchanged settings as soon as the power supply is restored.' The humid room air is drawn in from the front and cleaned of dust and dirt by a pull-out, easy-to-clean filter. The dried air is then blown out at the back. The display shows the currently measured humidity. The water extracted from the air can be collected in the inserted bucket or discharged directly through a hose (suitable inner diameter: 12 mm). A float automatically interrupts operation when the bucket is full. If the water is discharged through the hose, it first passes through the bucket to which the hose connector is attached. This system is very safe: if the hose is clogged, kinked, or not properly laid, the water backs up into the bucket. When the bucket is full, operation stops. Overflow onto the floor is therefore not possible, unlike dryers where the hose is directly attached to the drip tray. Important functions • Digital control and side-mounted operating hour meter• High efficiency thanks to automatic hot gas defrosting• Robust housing with two large running wheels and guide handle• Easy operation• Built-in hygrometer• Water container with automatic shut-off when full• Possibility to connect a hose for direct drainage of condensate• Air filter Suitable for • Drying of commercial spaces and archives• Drying of water damage• Building drying• Industry and Production• Rental Propane (R290) as an environmentally friendly refrigerant in dehumidifiers"Every year, several million tons of environmentally harmful CO2 emissions (greenhouse gases) are released into the air due to synthetic refrigerants. Therefore, the use of alternative refrigerants is one of our most important goals. By using propane (R290) as a refrigerant, this dehumidifier makes a valuable contribution to climate protection." The natural refrigerant propane (R290) is an organic compound and belongs to the hydrocarbons. Unlike synthetic refrigerants, environmentally friendly propane (R290) has neither ozone depletion potential (ODP=0) nor a significant greenhouse effect (GWP=3). "Supplement plus for the environment: Due to its excellent thermodynamic properties, propane (R290) is a particularly energy-efficient refrigerant, thereby additionally reducing your energy costs." Technical data dehumidification performanceat 20 °C / 60 % r.H.at 30 °C / 80 % r.H. 20.3 liters / day45.6 liters / day Air volume max. 350 m³/ h Maximum room size 115 m² (280 m³) Temperature range 5 - 35 °C Moisture range technical Moisture Range Practice 35 - 90 % r.F.40 - 90 % r.H. (lamella evaporator) voltage 220 - 240 V/50 Hz Nominal current consumption max. 4 A Power consumption max. 900 W Recommended Coverage 10 A Plug Connection cable with EU plug and Swiss fixed adapter refrigerant R290 (GWP: 3) Bucket + Hose connection 5.7 liter bucket and direct hose connection (suitable hose 12mm inner diameter) Operating noise 55 dB(A) at 1 m distance52 dB(A) at a distance of 3 m Masse (B x H x T) 422 x 820 x 580 mm Weight 30 kg Automatic defrosting Heissgas Attitude Digital Operator Panel Ventilator axial, single-stage blower Compressor Rolling piston Prefilter and operating hour meter and Continuous operation possible and Display and Memory function yes (set values saved on button press) Guarantee 2 years

Fr. 1'190.00

Krüger Krüger Airsec 11

Oasis dehumidifiers have been a common sight on construction sites for years. They are also well suited for keeping damp garages, archives, and basements dry. This new version under the "Krüger" brand replaces the previous "Airsec165" and is now called "Airsec11". The switch to the new, environmentally friendly refrigerant R290 also brings an improvement in the efficiency of the device. Additionally, the weight has been reduced by a good 2 kg, which provides relief, especially in professional use. Due to the stable, wide-mesh cooling part made of aluminum tubes, the Airsec/Oasis construction dryers are less susceptible to construction and gypsum dust and can be cleaned very easily.Characteristics• robust steel sheet housing• Front made of plastic• 4 four wheels, 2 side troughs/carry handles• removable coarse dust filter• mechanical hygrostat (therefore also suitable for operation with a timer)• Water container (8 liters) with float (interrupts operation when bucket is full)• Hose connection (3/4" thread at the bottom of the tub)• Light when bucket full• Heissgas-Abtauung• Cable with 3-pin Swiss plugRecommended Application ExamplesIn cooler basements, garages, civil protection facilities, winter construction sites, storage rooms dehumidification performanceThe dryer can be used over a wide temperature range from +3°C to +40°C thanks to hot gas defrosting, although, as with all condensation dryers, the dehumidifying power decreases in cooler environments. Examples of dehumidification performance under different (constant) ambient conditions:30°C / 80% r.H. 28 Liters / 24h28°C / 60% r.H. 16.8 Liters / 24h20°C / 60% r.H. 10.54 Liters / 24h15°C / 60% r.H. 7.19 Liters / 24h(r.H.=relative humidity)Tip The device is often placed on a wall console. In this case, the wheels should be removed and the device should be positioned sideways against the wall to ensure that the air intake (at the back of the device) is not blocked, allowing for optimal circulation. You can also obtain the pre-made consoles from the company Krüger from us.Tip No. 2: suitable coupling for hose connection"Order the original coupling for Oasis devices if you want to drain the water directly through a hose. Most commercially available couplings do not fit optimally due to the slightly altered connection thread of the collection tray." Technical data Krüger Art.-No. 343.01 Tension 230 V / 50 Hz Power consumption 360W normal operation (or 520W during defrosting process) Sound pressure level 1 m distance approx. 55dB (A) (our measurement) (Manufacturer's specification: 51 dB(A)) dehumidification performance 28 liters/day (30°C / 80% r.H.) amount of recirculated air 510 m³/h free blowing condensate tank approx. 8 liters (manufacturer's specification 9 L) Compressor Rotary compressor refrigerant R290 Dimensions (H x W x D) 560 x 38 x 36 cm Weight 23.5 Kg cessation of operations Hygrostatrad Ambient temperature 3°C ~ 40°C Area of application up to 80m² Swiss plug Yes hose connection Yes Guarantee: 2 years

Fr. 1'264.00

TROTEC Trotec dehumidifier DH 25 S

The DH25 is a powerful dehumidifier that is ideal for medium-sized rooms and environments with high humidity levels. It impresses with its reliable dehumidification performance in both cool and temperate spaces. As an evolution of the FDK44 model, it offers digital control and a slightly increased dehumidification capacity.OperationOperation is incredibly simple: The desired target humidity is set on the control panel. If the measured humidity exceeds the set value, the dehumidifier automatically starts operating; otherwise, it pauses. The display always shows the current room humidity. The DH25 unleashes its full dehumidification power especially for year-round drying of single or double garages, archives, basements, or for stabilizing humidity in laundry and drying rooms. Thanks to its highly advanced hot gas defrosting, the DH25 can be used down to just above freezing point. Its efficient dehumidification performance in low humidity ranges, where other dehumidifiers can no longer extract moisture from the air, is particularly noteworthy. The room air is drawn in from one side of the housing and cleaned through an industrial, reusable filter. The dried air is blown into the room from the opposite side, creating effective air circulation. The setup of the DH25 is flexible: it can be placed both on the floor and on a free shelf, with the wheels being lockable for a secure stand. The condensate is drained directly via a hose connection. It is important that the hose has a constant slope towards the drain to ensure smooth drainage. The DH25 is characterized by its solid and high-quality construction. The housing is made of white powder-coated metal, while the internal components meet professional standards. This allows for uninterrupted continuous operation without supervision. Even after a power failure, the dehumidifier resumes operation with the previous settings, making it ideal for use with timers or smart home systems. For easy mobility, the DH25 is equipped with four sturdy wheels (with brakes) and two foldable carrying handles. Versatile application• as a dehumidifier for warehouses, commercial and industrial spaces, garages, and basements• for continuous dehumidification of tempered but also cold rooms from 1°C• for unattended continuous operation• for operation on a timer dehumidification performanceThe dryer can be used thanks to advanced hot gas defrosting over a wide temperature range from +1°C to +35°C, although, as with all condensation dryers, the dehumidifying power decreases in cooler environments. Examples of dehumidification performance under different (constant) ambient conditions:30°C/80% r.H.: 40 liters20°C/80% r.H.: 16 Liters20°C/60% r.H.: 12 Liters10°C/60% r.H.: 7 Liters(r.H.=relative humidity) Optional accessoriesThe delivery includes the ready-to-plug-in device. If needed, we offer various suitable accessories, such as:• Hose coupling• Hose• Condensate pump (if the condensate needs to be pumped away to a higher location)Stronger designThe device is also available in double strength as "FDK100" -> DetailsComparable devices: Lunor L25 Technical data Model: Trotec DH25S Tension: 230V / 50Hz Power consumption: max. 700W / 510W (at 20°C/60% r.H.) Sound pressure level: (our measurement) 1 m distance 53 dB(A)2.5 m distance 51 dB(A) Dehumidification capacity: 40 liters/day (30°C / 80% r.H.) Air circulation volume: 450 m³/h (installed, free-blowing approx. 650 m³) Condensation tank: No tank / only hose connection possible Compressor: Rotary compressor Refrigerant: R290 (152gr.) Dimensions (L/H/D): 580 x 455 x 350 mm (including wheels and carrying handles) Weight: 30 Kg Business closure: Digital Ambient temperature: 1°C ~ 35°C Area of application: up to 100m² Swiss plug: EU plug with Swiss fixed adapter, 5m cable Hose connection: Yes Guarantee: 2 years

Fr. 1'290.00

TROTEC Trotec TTK570ECO Dehumidifier

A very powerful construction dehumidifier with brutal dehumidification strength. Perfect for drying large construction sites and for the effective drying of water damage. This dehumidifier has consistently omitted everything that is unnecessary for continuous operation. It has neither a display nor a hygrostat (a plug-in hygrostat can be optionally ordered if needed). This makes it very easy to operate, safe from tampering, and exceptionally affordable in price for this performance class. On the other hand, it has everything needed for quick drying: strong dehumidification performance, hot gas defrosting, hour counter, as well as large wheels and a handle for easy mobility on construction and damage sites. Easy handling "The commissioning is child’s play. Set up - connect the hose - plug in - flip the main switch - done!" The operation continues until the dryer is reinstalled. As long as the device is connected to the power grid, it runs reliably and there are no settings that can be accidentally changed or manipulated. This also applies in the event of a power outage: when the power returns, the dehumidifier resumes its task with unchanged settings. Thanks to the professional hot gas automatic control, operation in cooler environments is also possible without any issues, although the dehumidifying power, as with all condensation dryers, decreases at low temperatures. The installed finned evaporator (cooling element) has an exceptionally high efficiency in temperate environments and can dry the air to just below 40% relative humidity. Furthermore, the dryer is equipped with a rolling piston compressor. This means that it can be transported and stored in any position. Optional Hygrostat "Should a hygrometer for regulating the target humidity be required at any point, the dryer is prepared so that the Trotec Hygrostat HG110 can be connected directly via a jack plug. Please note the accessories." Direct hose connection With dryers of this strength, collecting water in an integrated bucket makes little sense, as it would constantly fill up. The water extracted from the air is therefore drained through a directly connected hose. The hose must be laid with a downward slope, as there is no pump integrated into the dryer. Freestanding condensate pumps are optionally available if the water needs to be transported upwards or over a distance. Suitable for unattended continuous operation This "TTK" is suitable for longer, unattended drying operations. The exact operating time can be precisely determined with the standard integrated hour meter. This is particularly useful for commercial applications. Thanks to the meter, it can also be tracked whether the device was always in operation or if it was accidentally or intentionally turned off. Hydrofluorolefin (R-454C) as an environmentally friendly refrigerant in dehumidifiers "Every year, several million tons of environmentally harmful CO2 emissions (greenhouse gases) are released into the air due to synthetic refrigerants. Therefore, the use of alternative refrigerants is one of our most important goals. By using hydrofluoroolefin (R-454C) as a refrigerant, this dehumidifier makes a valuable contribution to climate protection." The natural refrigerant hydrofluoroolefin (R-454C) is an organic compound and belongs to the hydrocarbons. Unlike synthetic refrigerants, the environmentally friendly hydrofluoroolefin (R-454C) has neither ozone depletion potential (ODP=0) nor a significant greenhouse effect (GWP=146). Supplement plus for the environment: Due to its excellent thermodynamic properties, hydrofluoroolefin (R-454C) is a particularly energy-efficient refrigerant, thereby additionally reducing your energy costs. Advantages at a Glance • Affordable price with strong performance in the commercial sector• Thanks to hot gas defrosting, it can also be used in cooler environments.• Robust steel construction with large wheels and guiding handle• Suitable for continuous operation• Thanks to the roll piston compressor, it is transportable and storable in any position.• External hygrometer connection Technical data dehumidification performance at 30 °C / 80 % r.H. 100 liters / day air volume 1000 m³/ h Maximum room size 250 m² (750 m³) Minimum room size 8 m² (30 m³) temperature range 5 - 32°C Moisture range technical Moisture Range Practice 30 - 90 % r.F. 40 - 90 % r.H. (lamella evaporator) Voltage 220 - 240 V/50 Hz rated current consumption max. 8.1 A Power consumption max. 1920W Recommended Coverage 16 A Cable length approx. 2 m Plug EU plug with Swiss adapter refrigerant R454C (1000g) GWP146 water bucket no bucket operating noise 67 dB(A) at 1 m distance 64 dB(A) at a distance of 2.5 m Dimensions L x W x H 538 x 698 x 1006 mm incl. guide rail and rollers Weight 64 kg defrosting automatic Heissgas dehumidification automation Continuous operation, an insertable mechanical hygrometer is optionally available. Ventilator radial, single-stage blower prefilter and operating hour meter and Continuous operation possible and Display no memory function yes (automatically saves set values) hose connection yes, not included in the delivery (suitable inner diameter: 12mm) guarantee 2 years

Fr. 1'490.00

Fral Fral FDK100 Large Room Dehumidifier

The top dryer for larger spaces. The FDK performs reliable heavy-duty work in both cooler and temperate rooms.The operation is incredibly simple: a rotary knob for adjusting the desired target humidity and that's it. Everything else is done automatically by the device. For example, the FDK can utilize its dehumidifying power for year-round drying of garages, industrial halls, or in water management facilities. You can only get this model from us; comparable products on the market cost twice as much.Due to well-developed hot gas defrosting, the dryer is operational down to just above freezing point. Also very noticeable is its good performance in low humidity ranges, where it still extracts water from the air, while other dryers have long stopped producing any drops. Upon reaching the desired target humidity, the device completely shuts off and automatically restarts when the room humidity increases.The humid air is drawn in on one side of the housing and cleaned through an industrial, reusable filter. The dry air is blown into the room from the opposite side, creating an effective circulation in the room. Regarding placement in the room, many locations are conceivable. Both at floor level, somewhere on a free shelf, or mounted to the wall with brackets. When wall-mounted, the dryer can also be installed high up directly under the ceiling.The condensate is drained directly through the hose connection. The FDK100 stands on 4 (removable) rubber feet and has two foldable carrying handles on the top of the housing for easier mobility. When positioned close to the ground, the hose must have a continuous slope towards the drain so that it can drain cleanly and does not back up into the collection tray.The construction is solid and of high quality. The housing is made of white powder-coated metal, and the interior consists of components from the professional league. Therefore, the device is easily suitable for unattended continuous operation. In the event of a power failure, it resumes the dehumidification work with unchanged settings, making it suitable for operation with a timer or a smart home system.The FDK is suitable• as a dehumidifier for warehouses, commercial and industrial spaces, garages, and basements• for wall mounting or directly on the ceiling• for continuous dehumidification of temperate but also cold rooms from 1°C• for unattended continuous operation• for operation on a timer dehumidification performanceThe dryer can be used over a wide temperature range from +1°C to +35°C thanks to its advanced hot gas defrosting, although, as with all condensation dryers, the dehumidifying power decreases in cooler environments. Examples of dehumidification performance under different (constant) ambient conditions: 30°C/80% r.H.: 80 liters / 24 h20°C/80% r.H.: 45 liters / 24 h20°C/60% r.H.: 30 liters / 24 h10°C/60% r.H.: 18 Liters / 24 h(r.H.=relative humidity)Optional accessoriesThe delivery includes the ready-to-plug-in device, including 4 stand feet for placement, e.g., on a shelf. If needed, we offer various suitable accessories for this dryer, such as:• 2 wall consoles for mounting on a wall (total Fr. 68.-)• Hose coupling• Hose• Condensate pump (if the condensate needs to be pumped upwards) Smaller versionThe device is also available in the smaller version "FDK44" -> DetailsComparable devices: Lunor L75 Technical data Tension 230V / 50Hz Power consumption 1020W (at 20°C/60% r.H.), max. 1550W Sound pressure level 1 m distance 58 dB(A) (our measurement) 2.5 m distance 56 dB(A) (our measurement) dehumidification performance 80 liters/day (30°C / 80% r.H.) amount of recirculated air 1100 m³/h (installed, free-blowing approx. 1350 m³/h) condensate tank No tank / only hose connection possible Compressor Rotary compressor refrigerant R410A Dimensions (L x H x D) 73 x 58 x 58 cm Weight 48 Kg cessation of operations Hygrostatrad Ambient temperature 1°C ~ 35°C Area of application bis 250m²/1000m³ Swiss plug Yes hose connection Yes guarantee 2 years

Fr. 2'046.00 Fr. 1'690.00

TROTEC Trotec TTK355S Luftentfeuchter

Trotec TTK 355 S – Kraftvoller Bautrockner für härteste Einsätze Ob bei der schnellen Reduktion hoher Luftfeuchtigkeit oder zur zuverlässigen Trocknung grossvolumiger Räume – der TTK 355 S ist exakt für solche Herausforderungen konzipiert. Seine beeindruckende Leistung verdankt das Gerät der effektiven Kombination eines leistungsstarken Rollkolbenkompressors mit einem Qualitätsgebläse, das Luftmengen von bis zu 490 m³/h verarbeitet. Diese hohe Luftumwälzung erlaubt es dem optimierten Wärmetauschersystem, kontinuierlich große Mengen Feuchtigkeit aus der Raumluft zu ziehen – bis zu 70 Liter pro Tag mit nur einem Gerät. Ein besonderes Plus bietet die integrierte Heissgas-Abtauautomatik: Sie verhindert Entfeuchtungspausen durch feste Abtauintervalle, wie sie bei vielen anderen Geräten üblich sind, und sorgt so für eine gleichmässige und effiziente Leistung – selbst bei kühleren Einsatzbedingungen. Mobilität trifft auf Robustheit Auch für wechselnde Einsatzorte und raue Umgebungen ist der TTK 355 S bestens gerüstet. Das robuste Fahrgestell mit praktischer Griffbügelstange und grossen Gummirädern macht den Transport – auch über Treppen oder unebenen Boden – denkbar einfach. Die verbauten Gummiräder sind abriebfest und hinterlassen keinerlei Spuren auf empfindlichen Bodenbelägen. Dank der Rollkolbenkompressor-Technologie kann der TTK 355 S zudem in nahezu jeder Position transportiert werden. Ein spezielles Schutzsystem für die Elektronik bewahrt die sensiblen Komponenten zuverlässig vor Feuchtigkeit und Schmutz – für eine lange Lebensdauer auch unter Baustellenbedingungen. Durchdachtes Design – innen wie aussen Auch optisch überzeugt der TTK 355 S: Die Technik steckt in einem funktional gestalteten, widerstandsfähigen Gehäuse im markanten Trotec-Industriedesign – formschön, geschützt und praxisorientiert. Der stapelbare Aufbau mit praktischen Nutführungen auf der Oberseite ermöglicht eine platzsparende Lagerung und einen sicheren Transport mehrerer baugleicher Geräte. Ihre Vorteile auf einen Blick: 100 % Trotec – Entwicklung, Design und Fertigung Hohe Entfeuchtungsleistung, auch bei niedrigeren Temperaturen Schutz der Elektronik vor Staub und Feuchtigkeit Wartungsfreundliche Konstruktion Einfaches Handling und flexibler Transport Rollkolbenkompressor: transportabel in jeder Lage Stapelbar für Lagerung und Transport Multistapelfähig mit baugleichen Modellen Integrierter Hitzeschutz für den Kompressor Deutsches Industriedesign mit Geschmacksmusterschutz Sicherer Betrieb bei hoher Wärme- und Feuchtelast Bei der Sanierung von Wasserschäden oder ähnlichen Anwendungen herrschen oft extreme Bedingungen: hohe Luftfeuchte bei gleichzeitig hohen Temperaturen. Dies stellt eine grosse Belastung für Kältetrockner dar. Die sogenannte „35er-Regel“ verdeutlicht die Problematik: Liegt die Raumtemperatur dauerhaft über 35 °C, sinkt die Lebensdauer herkömmlicher Kältetrockner drastisch – auf weniger als 35 %. Ursache ist der steigende Druck im Kältemittelkreislauf, der den Kompressor stark belastet. Zwar arbeiten die Geräte zunächst weiter, sie operieren aber weit über ihrer Belastungsgrenze, was zu vorzeitigem Ausfall führen kann. Adsorptionstrockner stellen unter solchen Bedingungen keine wirtschaftliche Alternative dar – ihr Energiebedarf ist bei vergleichbarer Entfeuchtungsleistung deutlich höher. Intelligente Schutzfunktion serienmässig Deshalb sind die TTK-S-Modelle mit einem intelligenten Kompressor-Hitzeschutz ausgestattet. Sensoren kontrollieren kontinuierlich die Temperaturentwicklung im Gerät. Bei Überhitzung schaltet sich der Kompressor automatisch ab, während der Ventilator weiterläuft. Sobald sich das System wieder im sicheren Temperaturbereich befindet, nimmt der Kompressor selbstständig den Betrieb wieder auf. Dieser Schutzmechanismus verlängert nicht nur die Lebensdauer des Geräts, sondern schützt zugleich die zu trocknenden Materialien und die Gebäudesubstanz vor hitzebedingten Schäden. Entfeuchtungsleistung bei 20 °C / 60 % r.F. 27 Liter / Tag bei 30 °C / 80 % r.F. 55 Liter / Tag Technische Daten Luftmenge Stufe max. 490 m³/h Raumgrösse 140 m² / 350 m³ Temperaturbereich min. 5 - 32 °C Feuchtebereich min. 40 - 90 % r.F. Netzanschluss 220 - 240 V, 50 Hz Nennstromaufnahme 6.1 A Leistungsaufnahme 1.4 kW empfohlene Absicherung 10 A Anschlussstecker EU-Stecker mit Schweizer Fixadapter Kabellänge 3 m Rollkolbenkompressor Kältemitteltyp R-454C Kältemittelmenge 650 g GWP Faktor 146 CO2 -Äquivalent 0.0949 t Druck Saugseite 0.6 Mpa Druck Austrittseite 2.2 Mpa max. zulässiger Druck 3 Mpa Masse (H x B x T) 725 x 380 x 390 mm Gewicht 39 kg Wassereimer 6 Liter + direkter Schlauchanschluss Schallpegel in Abstand 1 m 54 dB(A) Trotec Artikel-Nr. 1.120.000.163 Garantie 2 Jahre

Fr. 1'699.00

TROTEC Trotec TTK650S Dehumidifier

The 650S is a robust and powerful construction dryer that stands out for its versatility. It effortlessly handles demanding tasks such as drying after water damage, new construction drying, and maintaining dryness in heated and unheated storage rooms. Manufactured in a specialized European facility, this dehumidifier impresses with its high-quality workmanship and reliable operation. The durable construction of the 650S guarantees a long lifespan, while the easy maintenance and low upkeep costs make operation even more economical. Despite its impressive performance and quality, the 650S is available at an extremely attractive price, making it an excellent choice for professional users.Easy to use The desired target humidity can be continuously regulated between 32 - 100 % using a mechanical hygrostat, and continuous operation is also possible. Particularly useful in larger areas is the high air circulation volume of a substantial 925 cubic meters per hour. With its stable cart construction and large wheels, frequent changes of location can be easily carried out. Direct hose connection and optional pump kit Due to its very high dehumidification performance, this dehumidifier has a direct connection for condensate drainage instead of a water tank. The hose must have a slope towards the drain. If this is not possible, a suitable pump kit is optionally available, which can pump the water upwards and also outwards. The operating switch is protected against dust and splashes by a protective cover, and a slotted hygrostat rotary switch prevents unwanted adjustment of the switch position. Professional Hot Gas Defrosting Inside, a professional hot gas defrosting automatic system ensures effective dehumidification results. The fin evaporators unleash their power particularly in temperature ranges above 10°C and in the range above 40% humidity. Technically, the dryer can be used at room temperatures down to about 5°C, even in unattended continuous operation. Optional counters Included in delivery is no "Hour or consumption meters are included. You can order them from us upon request (the housing is standardly prepared for retrofitting). You have the choice between a pure hour meter or the combined dual meter, which measures hours and electricity consumption. The meters are MID compliant. Outside of Switzerland, dryers in professional use must already be MID compliant." Hydrofluoroolefin (R-454C) as an environmentally friendly refrigerant "Every year, several million tons of environmentally harmful CO2 emissions (greenhouse gases) are released into the air due to synthetic refrigerants. Therefore, the use of alternative refrigerants is one of our most important goals. By using hydrofluoroolefin (R-454C) as a refrigerant, this dehumidifier makes a valuable contribution to climate protection." The natural refrigerant hydrofluoroolefin (R-454C) is an organic compound and belongs to the hydrocarbons. Unlike synthetic refrigerants, the environmentally friendly hydrofluoroolefin (R-454C) has neither ozone depletion potential (ODP=0) nor a significant greenhouse effect (GWP=146). Advantages at a Glance • High dehumidification performance even at low temperatures• Robust plastic-coated metal housing• Thanks to the roll piston compressor, it is transportable and storable in any position.• Stable carriage construction• Automatic hygrostat-controlled dehumidification operation• Quality hot gas defrost automatic system• Option to retrofit MID-compliant dual meter for operating and kilowatt hours (optional) • Option to add a suitable pump kit that can be connected directly to the device (optional) Technical data dehumidification performanceat 30 °C / 80 % r.H. 91 liters / day Air volume 925 m³/ h Maximum room size 230 m² (550 m³) Minimum room size 4 m² Temperature range 5 - 32°C Moisture range technical Moisture Range Practice 32 - 90 % r.F. 40 - 90 % r.F. voltage 220 - 240 V/50 Hz Nominal current consumption max. 9.5 A Power consumption max. 2100 W Recommended Coverage 16 A Cable length approx. 3 m Plug EU plug with Swiss fixed adapter refrigerant R-454C (1050g) GWP 146 water bucket no bucket, only hose connection suitable hose: 16 mm inner diameter Operating noise 56 dB(A) at 1 m distance53 dB(A) at a distance of 2.5 m Dimensions L x W x H 616 x 511 x 1022 mm (incl. guide bracket) Weight 52 kg Automatic defrosting Heissgas dehumidification automation Hygrostatgesteuert Ventilator axial, single-stage blower Prefilter and Timer no (operation on timer possible) Continuous operation possible and Memory function yes (mechanically stores set values) hose connection yes (no hose included in the delivery) - 16 mm Pump optional available (not included in the delivery) Guarantee 2 years

Fr. 1'899.00

Aerial Aerial AD110P Wall-mounted Dehumidifier with Pump

High-quality dehumidifier for space-saving wall mounting, ideal for up to 30m². It is compact, quiet, and economical. Its high-quality stainless steel housing combines aesthetic demands with a long lifespan. A special feature of this dehumidifier is the slanted louvers. They allow the air to be released at the front of the device without drafts. This guarantees quiet operation with a noise level of only 46 dB. The air intake is located on the left side via an easily removable air filter, and the outlet of the dry air is on the front side. "In particular, in busy areas such as changing rooms and wellness areas, smaller fitness rooms, etc., the low noise level and draft-free air circulation are of great advantage."In contrast to the AD110 model, the 110P features a built-in pump that can discharge the condensate upwards and outwards, for example into a sink, into a higher or further away drain.The new digital control is easy to understand and displays the temperature, actual and target humidity, as well as the operating hours digitally.The assembly is quite simple: a support rail is screwed to the wall, and the dryer itself can then be easily hung in it. Rail, screws, and dowels are already included in the delivery. latest technologyThanks to the latest technology, it is highly efficient and economical. The refrigerant R1234rf has minimal environmental impact. Thus, the "Global Warming Potential (GWP)" is an incredible value of 4, which corresponds to a reduction of 99.5% compared to comparable models from previous generations. Characteristics Compact and space-saving Incl. wall mount Automatic pump with overflow protection New, environmentally friendly refrigerant Edelstahlhaube BlueDry technology for particularly energy-saving operation – even at low humidity and temperatures. Intelligent e-Dry Control operating hour meter Display of target and actual moisture For corporate clients: available upon request with a robust plastic housing in a color of your choice and with company logo, quantities and price upon request. Dehumidification performance / Power consumption at 30°C / 80% r.H. = 15 liters/day / 330 wattsat 20°C / 60% r.H. = 8.5 liters/day / 236 wattsat 15°C / 70% r.H. = 8 liters/day / 215 watts Technical data Tension 230 V / 50 Hz Power consumption max. 330W or 236W at 20°C/60% r.H. operating noise 1 m distance 46 dB(A) (our measurement) dehumidification performance 15 liters/day (30°C / 80% r.H.) amount of recirculated air 225 m³/h condensate tank integrated condensate pump, no tank hose connection Yes, 3m mounted on the device (12mm inner diameter) refrigerant R1234yf Weight 18.5 kg Masse (H x B x T) 49 x 33 x 28 cm cessation of operations Digital Ambient temperature 3°C ~ 32°C Plug Cable with Swiss plug T12 Area of application up to 30m² / 70m³ (temperature-controlled rooms) Ambient temperature 3°C ~ 32°C operating hour meter Yes Protection class IP54 guarantee 2 years

Fr. 1'935.00

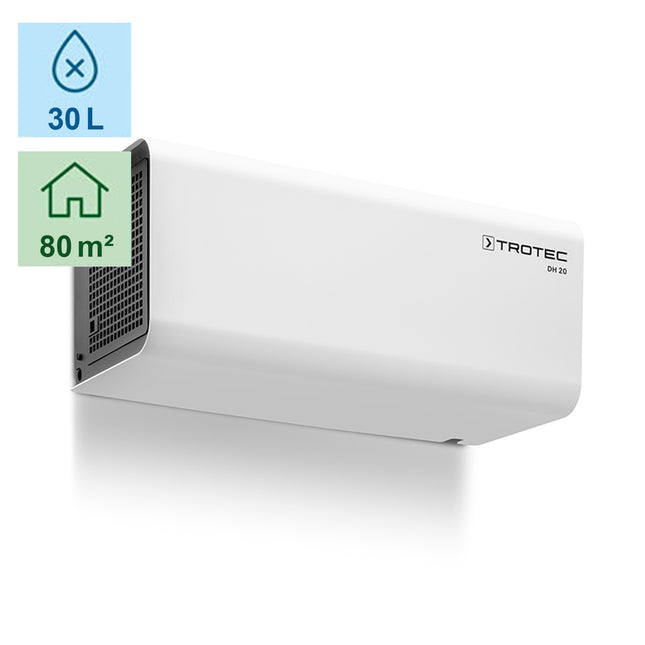

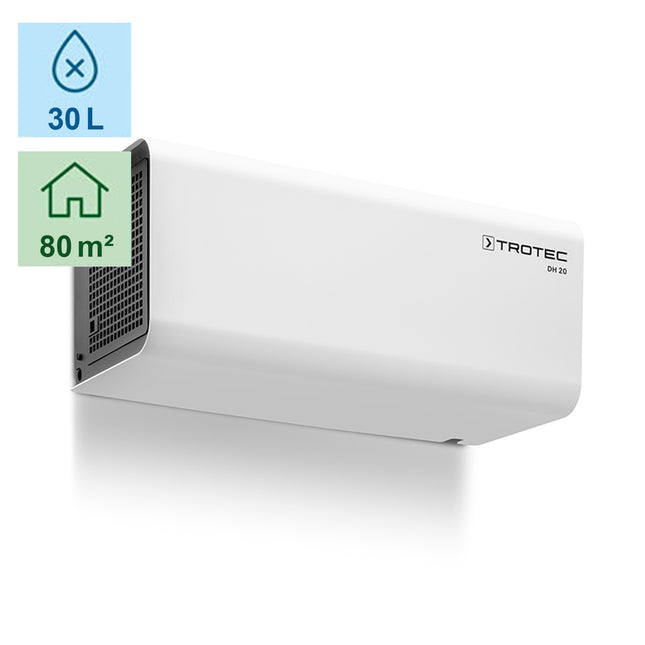

TROTEC Trotec Schwimmbad- und Gewerbeentfeuchter DH 20

Der kompakte Luftentfeuchter für an die Wand DH 20 eignet sich bestens für eine effektive Feuchtigkeitskontrolle in kleinen Gewerberäumen und zur Trocknung von feuchten Keller- und Archivräumen. Mit seiner Entfeuchtungsfähigkeit von bis zu 12,6 Litern pro Tag (bei 20 °C und 60 % relativer Luftfeuchtigkeit) hält er die Luftfeuchtigkeit präzise unter Kontrolle. Das beugt effektiv der Bildung von Schimmel vor und schützt so Ihre Räumlichkeiten und Materialien. Dank seiner länglichen Form passt der DH 20 auch über Türstürze und Wandschränke. Merkmale und VorteileDieses wandmontierte Gerät überzeugt nicht nur durch seine robuste Bauweise und sein benutzerfreundliches Design: Langlebigkeit: Das Aluminiumgehäuse und die kataphoretisch beschichteten Wärmetauscher bieten eine hohe Korrosionsbeständigkeit, was u.a. auch den Einsatz in Schwimmhallen ermöglicht. Präzise Feuchtigkeitsregelung: Ein elektronischer Hygrostat regelt die Luftfeuchtigkeit automatisch auf den gewünschten Wert. Benutzerfreundlichkeit: Das intuitive Bedienfeld und die einfache Installation machen die Handhabung des DH20 unkompliziert. Praktischer Wasserablauf: Der direkte Wasserablauf erspart das Entleeren eines Tanks. Das entzogene Kondensat wird über einen fallend installierten Schlauch in einen nahen Abfluss geleitet. Wandmontage: Das Modernes Design: Das unauffällige und moderne Design fügt sich nahtlos in jede Umgebung ein. Technische Daten Spezifikation Wert Betriebstemperaturbereich 5 - 40 °C Betriebsfeuchtigkeitsbereich 40 - 80 % Luftdurchsatz 375 m³/h Schalldruckpegel (in 1 m Abstand) 48 dB(A) Entfeuchtungsleistung (30°C/80% r.F.) 30 L/24h Entfeuchtungsleistung (20°C/60% r.F.) 12.6 L/24h Verbrauch (30°C/60% r.F.) 0.66 kWh/L Verbrauch (20°C/60% r.F.) 0.82 kWh/L Gasgewicht R290C/CO₂-Äquivalent 0.15 kg / 0.0005 t Stromspannung 230 V / 1 Ph / 50 Hz Stromverbrauch (max.) 0.51 kW Nennstromstärke (max.) 2.3 A Masse (B x T x H) 900 x 350 x 365 mm Gewicht 33 kg Garantie 2 Jahre

Fr. 1'949.95

TROTEC Trotec Industrial Dehumidifier DH15

A reliable wall-mounted dehumidifier with an appealing design. A durable, corrosion-protected construction made of powder-coated, galvanized steel sheet ensures maximum reliability for this industrial condensate dryer and makes it particularly resistant to environmental influences thanks to its protective-coated heat exchanger. The combination of high efficiency and low-maintenance design makes the dryer ideally suited for fully automatic, hygrostat-controlled continuous drying applications in numerous fields of use, and thanks to its autonomous recirculation operation, it can also be easily integrated into any application environment afterwards. With its KTL-coated heat exchanger, it is also extremely resistant to environmental influences even in particularly reactive air environments with high salt, chlorine, or solvent content. Hygrostat controlled and protection against manipulation The built-in hygrostat automatically regulates the humidity to an optimal level, where condensation, mold, or corrosion have no chance. The target humidity can be freely adjusted according to your needs. High efficiency is ensured by the quiet-running AC axial fan and the powerful compression refrigeration system. The dry air supplied to the room is simultaneously heated for process technology, so that the use of conventional heating and ventilation energy can be reduced. Thanks to high-quality hot gas automation, the dryer requires only very short defrosting phases. This is optimal, especially for dehumidifying unheated rooms, as it improves the performance and increases efficiency. The controls are protected against unauthorized access, making this industrial dryer also the ideal dehumidifier for public buildings, staff and changing rooms, or museums. Wide range of applications In wall operation, the device can be used for a variety of applications, for example: • Humidity control in staff rooms, changing rooms, lounges, and break rooms• Drying of changing rooms, gyms, bike and ski cellars• Constant humidity conditions in garages, workshops, test benches, or production halls• Dehumidification in archives, collections, or libraries• Dehumidification of water engineering facilities and pumping stations to prevent condensate formation on pipes or pumps• Humidity control during the storage of natural products, for example for quality assurance in wood storage or during the storage of raw tobacco.• Corrosion prevention in electrical switchgear, boiler systems, turbines, and piping systems in power plants or during the storage of raw bodies and metal components.• Humidity control in data centers, control rooms, etc.• Moisture control in the food industry, for example in cheese production or confectionery manufacturing Due to the horizontally directed recirculation airflow and its compact design, the plug-and-play dehumidifier is particularly well suited for installation above door areas. The condensate drawn from the air is directly drained through a downward laid hose. If the water needs to be drained to higher areas, please also consider our pump kits. Advantages at a Glance • Professional quality, made in Germany• High dehumidification performance even at low temperatures• Corrosion-protected construction• Fully automatic operation• Professional hot gas defrosting automatic system• Quiet AC axial fan for horizontal recirculation airflow• Optimal suited for installation above door areas• Control elements installed protected from unauthorized access• Available optionally with condensate pump Technical data dehumidification performance at 20 °C / 60 % r.H. at 30 °C / 80 % r.H. 11 liters / day 22 liters / day air volume max. 225 m³/ h Maximum room size 60 m² (150 m³) temperature range 5 - 40°C Moisture range technical Moisture Range Practice 30 - 90 % r.F. 40 - 90 % r.H. (lamella evaporator) Voltage 220 - 240 V/50 Hz rated current consumption max. 3.7 A Power consumption max. 657W Recommended Coverage 10 A Plug approx. 3.5m connection cable with EU plug and Swiss fixed adapter refrigerant R-407C (480g) GWP1774 hose connection Direct hose connection, no bucket suitable hose 10mm inner diameter short hose piece included in the delivery operating noise 53 dB(A) at 1 m distance 49 dB(A) at a distance of 3 m Masse (B x H x T) 840 x 330 x 365 mm Weight 37 kg defrosting automatic Heissgas dehumidification automation mechanical hygrostat wheel, stepless Ventilator axial, single-stage blower prefilter and operating hour meter no Continuous operation possible and Display no memory function yes (set values remain mechanically fixed) Trotec article no. 1.125.000.111 guarantee 2 years Documents / Downloads User Manual German User manual French User manual Italian User manual English

Fr. 2'200.00

Aerial Aerial AERCUBE AD40 Dehumidifier

The AD40 is versatile and so lightweight that it can be carried like a suitcase. Thanks to the BlueDry® technology, the AD40 dehumidifies consistently and reliably even at low humidity and temperature.serviceThe operation is simple and is carried out via the innovative eDRY® electronics. All control elements are clearly arranged, and all important operating states are accessible at any time. The display shows the target and actual humidity. Operating hours (consumption) can be easily read. The energy consumption is displayed via the additional calibrated energy meter. The control is equipped with a memory function. This means that in the event of a power failure, for example on construction sites, the operation will resume with unchanged settings as soon as the power supply returns.Water bucket or optional pumpThe water collection container (6.8 liters) is easy to remove, carry, and empty. It is located inside, with the water level of the bucket measured by a float. When full, it automatically interrupts operation, and operation automatically restarts when the bucket is replaced. An optional matching pump kit is available, which is versatile and suitable for unattended continuous operation.Robust housingThe housing is easy to clean and can be easily disassembled for any necessary service work. It features a foldable handle. Tie-down straps can be attached on the sides. The secured socket is used for connecting additional devices. Four robust, stable plastic feet for floor placement. Stackable with other Aerial Aercube devices.Characteristics • Case: made of robust, impact-resistant, and UV-resistant plastic, lightweight. Fixed points for AERCUBE® lashing system. • Cable: integrated cable winder.• Setup: freestanding or mounted on Aercube system (fixation points for AERCUBE lashing system).• Airflow: cross, lateral intake and exhaust.• Air filter: Protects the device from dust.• Fan: 2-stage, energy-efficient EC fan.• Defrosting: Demand-controlled hot gas defrosting.• Condensate pump: Optional pump kit available.• Blue-Dry Technology: For particularly energy-saving operation – even at low humidity and temperatures.• Calibrated energy meter (MID compliant).• Memory Function: After a power interruption, it resumes operation with unchanged settings. Therefore, it is also suitable for operation with, for example, a timer. • Hot gas defrosting: Thanks to automatic self-defrosting, it can also be used in cooler environments.• Suitable for unattended continuous operation.• Custom design: available in all colors and with your logo for larger quantities. All AERCUBE system components are 100% compatible and stackable with each other. Aerial "eDRY®" for efficient air dehumidification"A prerequisite for an economical operation and reduced energy consumption is the optimal coordination of the components and the use of advanced measurement and control technology. With the development of "eDRY", Aerial was able to further improve the user-friendliness and energy efficiency of the AD series. The use of digital precision sensors in conjunction with the eDRY electronics enables very accurate measurement and control of the room humidity." dehumidification performanceThe dryer can be used thanks to advanced hot gas defrosting over a wide temperature range from +1°C to +34°C, although, as with all condensation dryers, the dehumidifying power decreases in cooler environments. Examples of dehumidification performance and consumption under various (constant) ambient conditions:30°C / 80% r.H = 35.0 Liters / 24h (Power consumption: 520W) 27°C / 60% r.H. = 22.0 Liters / 24h (Power consumption: 430W) 20°C / 60% r.H. = 15.0Liters / 24h (Power consumption: 370W) 10°C / 70% r.H. = 8.0 Liters / 24h (Power consumption: 300W)(r.H.=relative humidity) Technical data Tension: 230V / 50Hz Power consumption: max. 530W Sound pressure level: 1 m distance 57 dB(A) 2.5 m distance 54 dB(A) 3 m distance 53 dB(A) Dehumidification capacity: max. 35.0 liters / day (30°C / 80% r.H) Bucket: Capacity 6.8 liters, Operational interruption due to swimmer Recirculation air volume level 1 / 2: 300 / 400 m³/h refrigerant: R407C Dimensions (H/W/D): 580 / 390 / 450 mm Weight: 25 Kg Business closure: Digital Ambient temperature: +1°C - +34°C Application area: up to approx. 100 m² Swiss plug: Yes hose connection: Connection fitting for direct hose connection Optional Pump Kit Operating hour meter: Yes Guarantee: 2 years Documents / Downloads User Manual German

Fr. 2'380.00

Dantherm Dantherm CDF10 Dehumidifier, white

Massively built wall unit for dehumidifying rooms up to 25m2/70m2, ideal for bathrooms, saunas, archives, or hobby rooms. The device is available in two versions, with and without a condensate tank (direct hose connection is possible for both versions), color silver or white.The air intake is at the front, and the dry air is expelled on both sides. For good circulation, the CDF10 should therefore have at least 30 cm of free space on each side. The device automatically switches off at temperatures below 3°C. Recommended ambient temperature 8-30°C."What is special about the CDF10 is that the hygrostat switch (for setting the desired room humidity) is located behind the front panel, which is secured with two screws. This protects it from unauthorized changes to the target humidity. Therefore, the CDF10 is particularly well-suited for public spaces."The wall mounting is done using the wall bracket included in the delivery, and the condensate is drained via the hose connection at the bottom of the dehumidifier (the hose must slope downwards, as no pump is integrated). Alternatively, the dryer is also available with an integrated 5.5-liter bucket for collecting the water. The CDF10 is one of the quieter dehumidifiers. The operating noise is audible in the immediate vicinity, but hardly noticeable with closed doors. This model is offered identically under the name of the Danish manufacturer "Dantherm" as well as "Krüger CDF10." Technical dataVoltage: 230 V AC, Swiss plugPower consumption: 300W max.Coverage: 2.1 A/TSound pressure level: 1m distance 49 dB(A)2.5 m distance 46 dB(A) Dehumidification capacity: 10 liters/day (30°C / 80% r.H.) Refrigerant: R134a (190g)Dimensions (H/W/D): 60 x 54 x 25 cm without tank81.5 x 54 x 25 with tankWeight: 28 kg without tank30 kg with tankAmbient temperature: 8°C ~ 30°C (our recommendation)Warranty: 2 years

Fr. 2'549.00

Aerial Aerial AD935 Dehumidifier

Drying technology at the latest standard! The 9 series of Aerial construction dryers has been completely developed to meet the needs for use on construction sites, in industry, and for water damage drying. The dryers come standard with a MID-approved kWh meter as well as a non-resettable hour meter. Thanks to the CC 6 control, the devices are compatible with the remote monitoring solution "Simplify," allowing for convenient remote operation monitoring.The AD-935 features both an 8-liter condensate tank and a connection nozzle for direct drainage of the condensate via a hose. Additionally, a suitable pump kit is available, which automatically recognizes the device upon installation. The humid room air is drawn in at the front of the housing, and the dry air is blown out at the back. In the intake area, a reusable industrial filter mat cleans the air and ensures that flying particles do not enter the device. service The operation is carried out via the operator panel mounted on the side. With just three buttons, it is comfortable and clear. It displays all important information, and the desired values can be set at the push of a button.• Simple 3-button operation • Color-coded status display of room conditions - red, yellow, green • Complete graphic display, no translation required High service friendliness The housing has been designed to be opened with minimal effort. This allows internal components to be easily and quickly cleaned or replaced if necessary. Features at a glance • Control unit CC 6 compatible with the remote monitoring solution Simplify• OEM versions available on request (minimum order quantity 50)• The use of standardized components from the Dantherm Group's product portfolio ensures quick access to spare parts.• Integrated interface for accessories (dew point kit and external hygrostat)• Automatic detection of the pump kit• Various drainage options: Standard with Ø15mm hose connection, water tank, and optional pump set• MID-approved kWh meter and non-resettable hour meter as standard• 2-stage fan • Integrated night mode for quieter operation in inhabited rooms• R454C refrigerant, non-toxic and non-flammable, with extremely low GWP (Global Warming Potential)• Large wheels• Telescopic Handle• Stackable• Maintenance and service friendly dehumidification performance The dryer can be used over a temperature range of +5 °C to +30 °C, with the dehumidifying power decreasing in cooler environments, as is the case with all condensation dryers. Examples of dehumidification performance and consumption under various (constant) environmental conditions:30°C / 80% r.H. = 34.0 liters / 24h (Power consumption: 610 W)20°C / 60% r.H. = 16.5 liters / 24h (Power consumption: 450 W)(r.H.=relative humidity) Technical data Tension 230V / 50Hz Power consumption 610 W max. Sound pressure level 2.5 m distance 51 dB(A) dehumidification performance 34 liters/day (30°C / 80% r.H.) condensate tank Approx. 8 liters Air volume level 1 / 2 300 / 420 m³/h (Night mode: 300 m³/h) Compressor Rotary compressor refrigerant R454C Dimensions (H x W x D) 860 x 392 x 508 mm Weight 35.4 Kg cessation of operations CC 6-Operating Panel, wireless connection with Simplify remote monitoring possible Ambient temperature ambient humidity 5 °C - 30 °C 30 % r.F. - 90 % r.F. Swiss plug Yes, cable length approx. 5 m hose connection 15 mm hose inner diameter guarantee 2 years

Fr. 2'591.00

Aerial Aerial AD935S Dehumidifier

Drying technology at the latest standard! The 9 series of Aerial construction dryers has been completely developed to meet the needs for use on construction sites, in industry, and for water damage drying. The dryers come standard with a MID-approved kWh meter as well as a non-resettable hour meter. Thanks to the CC 6 control, the devices are compatible with the remote monitoring solution "Simplify," allowing for convenient remote operation monitoring.The AD-935S features both an 8-liter condensate tank and a connection nozzle for directly draining the condensate via a hose. Additionally, a suitable pump kit is available, which automatically detects the device upon installation. The humid room air is drawn in at the front of the housing, and the dry air is blown out at the back. The air is expelled through two Ø100mm nozzles, which blow the air into the room at a good speed. Air hoses can also be attached to these nozzles if the dry air needs to be directed precisely to a specific location. In the intake area, a reusable industrial filter mat cleans the air and ensures that flying particles do not enter the device. service The operation is carried out via the operator panel mounted on the side. With just three buttons, it is comfortable and clear. It displays all important information, and the desired values can be set at the push of a button.• Simple 3-button operation • Color-coded status display of room conditions - red, yellow, green • Complete graphic display, no translation required High service friendliness The housing has been designed to be opened with minimal effort. This allows internal components to be easily and quickly cleaned or replaced if necessary. dehumidification performance The dryer can be used over a temperature range of +5 °C to +30 °C, with the dehumidifying power decreasing in cooler environments, as is the case with all condensation dryers. Examples of dehumidification performance and consumption under various (constant) environmental conditions:30°C / 80% r.H. = 28.0 liters / 24h (Power consumption: 785 W)20°C / 60% r.H. = 13 liters / 24h (Power consumption: 560 W)(r.H.=relative humidity) Features at a glance • Control unit CC 6 compatible with the remote monitoring solution Simplify• OEM versions available on request (minimum order quantity 50)• The use of standardized components from the Dantherm Group's product portfolio ensures quick access to spare parts.• Integrated interface for accessories (dew point kit and external hygrostat)• Automatic detection of the pump kit• Various drainage options: Standard with Ø15mm hose connection, water tank, and optional pump set• MID-approved kWh meter and non-resettable hour meter as standard• 1-stage fan • Integrated night mode for quieter operation in inhabited rooms• R454C refrigerant, non-toxic and non-flammable, with extremely low GWP (Global Warming Potential)• Large wheels• Telescopic Handle• Stackable• Equipped with a 1kW electric heating element and 2x Ø100mm duct connections• Maintenance and service friendly Technical data Tension 230V / 50Hz Power consumption 785 W max. (1785 W with additional heating) Recording supplementary heating +1000W Sound pressure level 2.5 m distance 53 dB(A) dehumidification performance 28 liters/day (30°C / 80% r.H.) condensate tank Approx. 8 liters air volume 400 m³/h Compressor Rotary compressor refrigerant R454C Dimensions (H x W x D) 860 x 391 x 505 mm Weight ca. 36 Kg cessation of operations CC 6-Operating Panel, wireless connection with Simplify remote monitoring possible Ambient temperature ambient humidity 5 °C - 30 °C 30 % r.F. - 90 % r.F. Swiss plug Yes, cable length approx. 5 m hose connection 15 mm hose inner diameter guarantee 2 years

Fr. 2'804.00

Aerial Aerial AD740 Dehumidifier

A powerful dehumidifier for construction sites and industry. The strong blower provides a wide-area exchange of moist and dry air. It features a housing made of impact-resistant plastic, two large wheels, and a foldable handle for easy movement on the floor and even up stairs. The intake of moist air is at the back via easily removable air filters. The dry air is blown out at the front through slanted slats.Characteristics• Fan: Axial fan with aluminum impeller. Motor with winding protection.• Compressor: Fully hermetic rotary piston compressor, protected against overload, mounted with vibration damping.• Condenser/Evaporator: made of copper pipes with attached aluminum fins• Self-defrosting: automatic hot gas defrost controlled by DryLogic, thus usable down to the freezing point.• Collection container: 6.8 liters with automatic full level shut-off• Hose connection: Socket (15 mm) for direct condensate drainage. Pump optionally available.• Hygrostat: digital with hygrostat rotary knob• Operating Hour Meter• Consumption meter kWh: calibrated, can be read without power• 2 large transport wheels: for easy mobility on construction and damage sites• Memory Function: After a power interruption, it resumes operation with unchanged settings. Therefore, it is also suitable for operation with, for example, a timer.• Suitable for unattended continuous operation.Aerial "eDRY®" for efficient air dehumidification"A prerequisite for an economical operation and reduced energy consumption is the optimal coordination of the components and the use of advanced measurement and control technology. With the development of "eDRY", Aerial was able to further improve the user-friendliness and energy efficiency of the AD series. The use of digital precision sensors in conjunction with the eDRY electronics enables very accurate measurement and control of the room humidity." dehumidification performanceThe dryer can be used thanks to advanced hot gas defrosting over a wide temperature range from +1°C to +34°C, although, as with all condensation dryers, the dehumidifying power decreases in cooler environments. Examples of dehumidification performance and consumption under various (constant) ambient conditions: at 30°C / 80% r.H. = 37.0 liters / day (Power consumption: 520 W)at 27°C / 60 % r.H. = 23.0 liters / day (Power consumption: 430 W)at 20°C / 60% r.H. = 16.5 liters / day (Power consumption: 390 W)at 10°C / 70% r.H. = 8.0 liters / day (Power consumption: 320 W) Technical data Tension: 230V / 50Hz Power consumption: max. 520 W (10A) / 390W (at 20°C/60% r.H.) Sound pressure level: 2.5 m distance 51 dB(A) (manufacturer's specification) Dehumidification capacity: max. 37 liters/day (30°C / 80% r.H.) Recirculation air volume level 1/2: 450 / 550 m³/h condensate tank: approx. 6.8 liters Compressor: Rotary compressor refrigerant: R407c (550gr.) Dimensions (H / W / D): 690 x 390 x 470 mm Weight: 32 Kg Business closure: Digital Operator Panel Ambient temperature: 1°C ~ 34°C (35 - 99% r.H.) Application area: up to 100m² / 300m³ Swiss plug: Yes hose connection: Yes Operating hour meter: Yes Guarantee: 2 years

Fr. 2'890.00

Aerial Aerial AD955 Dehumidifier

Drying technology at the latest standard! The 9 series of Aerial construction dryers has been completely developed to meet the needs for use on construction sites, in industry, and for water damage drying. The dryers come standard with a MID-approved kWh meter as well as a non-resettable hour meter. Thanks to the CC 6 control, the devices are compatible with the remote monitoring solution "Simplify," allowing for convenient remote operation monitoring.The AD-955 features both a 13-liter condensate tank and a connection nozzle for directly draining the condensate via a hose. Additionally, a suitable pump kit is available, which automatically recognizes the device upon installation. The humid room air is drawn in at the front of the housing, and the dry air is blown out at the back. In the intake area, a reusable industrial filter mat cleans the air and ensures that flying particles do not enter the device. service The operation is carried out via the operator panel mounted on the side. With just three buttons, it is comfortable and clear. It displays all important information, and the desired values can be set at the push of a button.• Simple 3-button operation • Color-coded status display of room conditions - red, yellow, green • Complete graphic display, no translation required High service friendliness The housing has been designed to be opened with minimal effort. This allows internal components to be easily and quickly cleaned or replaced if necessary. Features at a glance • Control unit CC 6 compatible with the remote monitoring solution Simplify• OEM versions available on request (minimum order quantity 50)• The use of standardized components from the Dantherm Group's product portfolio ensures quick access to spare parts.• Integrated interface for accessories (dew point kit and external hygrostat)• Automatic detection of the pump kit• Various drainage options: Standard with Ø15mm hose connection, water tank, and optional pump set• MID-approved kWh meter and non-resettable hour meter as standard• 2-stage fan • Integrated night mode for quieter operation in inhabited rooms• R454C refrigerant, non-toxic and non-flammable, with extremely low GWP (Global Warming Potential)• Large wheels• Telescopic Handle• Stackable• Maintenance and service friendly dehumidification performance The dryer can be used over a temperature range of +5 °C to +30 °C, with the dehumidifying power decreasing in cooler environments, as is the case with all condensation dryers. Examples of dehumidification performance and consumption under various (constant) environmental conditions:30°C / 80% r.H. = 53 liters / 24h (Power consumption: 830 W)20°C / 60% r.H. = 22.5 liters / 24h (Power consumption: 560 W)(r.H.=relative humidity) Technical data Tension 230V / 50Hz Power consumption 830 W max. Sound pressure level 2.5 m distance 53 dB(A) dehumidification performance 53 liters/day (30°C / 80% r.H.) condensate tank Approx. 13 liters Air volume level 1 / 2 290 / 550 m³/h (Night mode: 290 m³/h) Compressor Rotary compressor refrigerant R454C Dimensions (H x W x D) 845 x 452 x 538 mm Weight 41.8 Kg cessation of operations CC 6-Operating Panel, wireless connection with Simplify remote monitoring possible Ambient temperature ambient humidity 5 °C - 30 °C 30 % r.F. - 90 % r.F. Swiss plug Yes, cable length approx. 5 m hose connection 15 mm hose inner diameter guarantee 2 years

Fr. 3'330.00

Aerial Aerial AD750 Dehumidifier

The Aerial AD 750 is a very powerful, robustly built dehumidifier for construction sites and industry. The strong blower provides a wide-area exchange of moist and dry air. The AD750 features a robust housing made of impact-resistant plastic, stable guide rails, and side wheels for easy mobility on the floor. The dryer can even be pulled over stairs with these wheels. However, when used as a construction site dehumidifier, attention should be paid to the weight; 2 people are required for relocating it between floors or construction scaffolding.The intake of moist air is at the back via easily removable air filters. The dry air is blown out at the front through slanted slats.Characteristics• Fan: Axial fan with aluminum impeller. Fan motor with winding protection.• Compressor: Fully hermetic rotary vane compressor, protected against overload, mounted with vibration damping.• Condenser/Evaporator: made of copper pipes with aluminum fins. Refrigeration circuit made of copper pipe with capillary tube and filter drier. Service connection on the suction side.• Self-defrosting: Automatic hot gas defrost controlled by DryLogic.• Collection container: 12 liters, with automatic full level shut-off.• Hose connection: Fitting (15 mm) for direct condensate drainage.• Hygrostat: Hygrostat rotary knob• operating hour meter• 2 large transport wheels: good mobility thanks to 2 large transport wheels, ergonomically shaped housing.• Stackable designsThere are two versions of the AD750: with a bucket without a pump or with a pump without a bucket. Please select the desired model. dehumidification performanceThe dryer can be used over a wide temperature range from +3°C to +32°C thanks to its advanced hot gas defrosting, although, as with all condensation dryers, the dehumidifying power decreases in cooler environments. Examples of dehumidification performance and consumption under various (constant) environmental conditions: at 30°C / 80% r.H. = 55.0 liters / day (power consumption: 900 W)at 27°C / 60 % r.H. = 34.1 Liters / Day (Power consumption: 780 W)at 20°C / 60% r.H. = 24.5 liters / day (power consumption: 660 W)at 10°C / 70% r.H. = 14.0 Liters / Day (Power consumption: 560 W) Technical data Tension: 230V / 50Hz Power consumption: max. 900W (10A) / 660W (at 20°C/60% r.H.) Sound pressure level: 2.5 m distance 53 dB(A) (manufacturer's specification) Dehumidification capacity: 55 liters/day (30°C / 80% r.H.) air circulation volume: 710 m³/h (measurement installed) condensate tank: approx. 12 liters Compressor: Rotary compressor refrigerant: R407c (550gr.) Dimensions (H/W/D): 88 x 52 x 49.5 cm Weight: 42 Kg Business closure: Hygrostatrad Ambient temperature: 3°C ~ 32°C (40 - 95% r.H.) Application area: up to 600m³ (temperature-controlled rooms) resp. 400m³ (unheated) Swiss plug: Yes hose connection: Yes Operating hour meter: Yes Guarantee: 2 years

Fr. 3'458.00

Aerial Aerial AD975 Dehumidifier with Pump

Drying technology at the latest standard! The 9 series of Aerial construction dryers has been completely developed to meet the needs for use on construction sites, in industry, and for water damage drying. The dryers come standard with a MID-approved kWh meter as well as a non-resettable hour meter. Thanks to the CC 6 control, the devices are compatible with the remote monitoring solution "Simplify," allowing for convenient remote operation monitoring.Due to its high dehumidification performance, the AD-975 is equipped with a water pump as standard. The humid room air is drawn in at the front of the housing, and the dry air is blown out at the back. In the intake area, a reusable industrial filter mat cleans the air and ensures that flying particles do not enter the device. service The operation is carried out via the operator panel mounted on the side. With just three buttons, it is comfortable and clear. It displays all important information, and the desired values can be set at the push of a button.• Simple 3-button operation • Color-coded status display of room conditions - red, yellow, green • Complete graphic display, no translation required High service friendliness The housing has been designed to be opened with minimal effort. This allows internal components to be easily and quickly cleaned or replaced if necessary. Features at a glance • Control unit CC 6 compatible with the remote monitoring solution Simplify• OEM versions available on request (minimum order quantity 50)• The use of standardized components from the Dantherm Group's product portfolio ensures quick access to spare parts.• Integrated interface for accessories (dew point kit and external hygrostat)• Standard equipped with pump set, no bucket• MID-approved kWh meter and non-resettable hour meter as standard• 2-stage fan • Integrated night mode for quieter operation in inhabited rooms• R454C refrigerant, non-toxic and non-flammable, with extremely low GWP (Global Warming Potential)• Large wheels• Telescopic Handle• Maintenance and service friendly dehumidification performance The dryer can be used over a temperature range of +5 °C to +30 °C, with the dehumidifying power decreasing in cooler environments, as is the case with all condensation dryers. Examples of dehumidification performance and consumption under various (constant) environmental conditions:30°C / 80% r.H. = 76 liters / 24h (Power consumption: 1070 W)20°C / 60% r.H. = 34.5 liters / 24h (Power consumption: 785 W)(r.H.=relative humidity) Technical data Tension 230V / 50Hz Power consumption 1070 W max. Sound pressure level 2.5 m distance 64 dB(A) dehumidification performance 76 liters/day (30°C / 80% r.H.) water pump standard (no bucket), lift height 4 m Air volume level 1 / 2 750 / 900 m³/h (Night mode: 750 m³/h) Compressor Rotary compressor refrigerant R454C Dimensions (H x W x D) 906 x 502 x 547 mm Weight 48.3 Kg cessation of operations CC 6-Operating Panel, wireless connection with Simplify remote monitoring possible Ambient temperature ambient humidity 5 °C - 30 °C 30 % r.F. - 90 % r.F. Swiss plug Yes, cable length approx. 5 m hose connection 15 mm hose inner diameter guarantee 2 years

Fr. 3'813.00

Aerial Aerial AD750P Dehumidifier with Pump